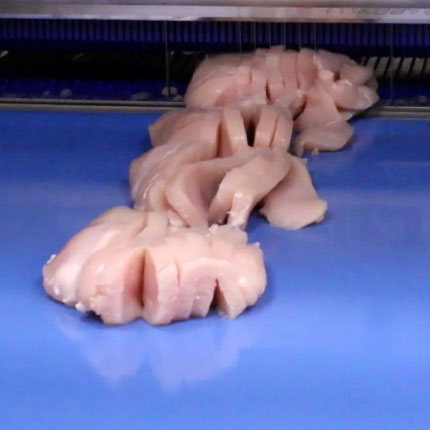

The future in vertical slicing, on weight.

Portion cutter for weight controlled vertical slicing of fresh boneless products.

Portion cutter for weight controlled vertical slicing of fresh boneless products.

With a capacity of up to 60 trays/min, ATF allows for maximum flexibility and significant cost reduction, for an automated process with the least handling of the product.

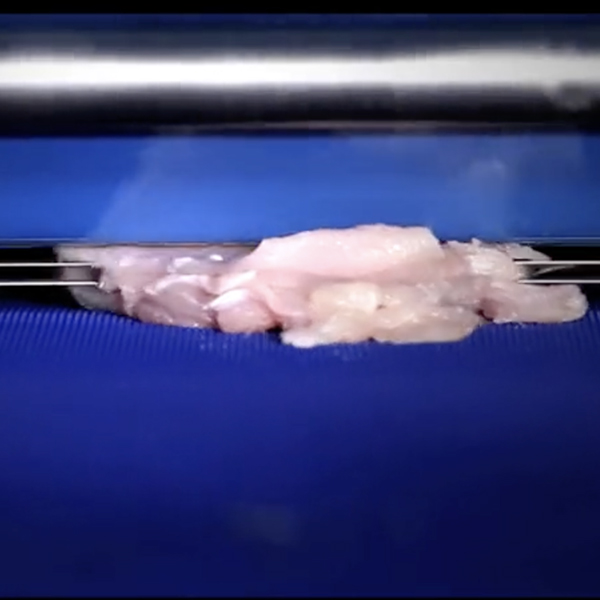

Fully automatic membrane skinner for poultry for in-line solutions. Constant output and efficiency over time, thanks to specially made pressure rollers, easily adjustable and extremely robust construction.

Compact skinning (C35 M) and derinding (C35 P) machine.

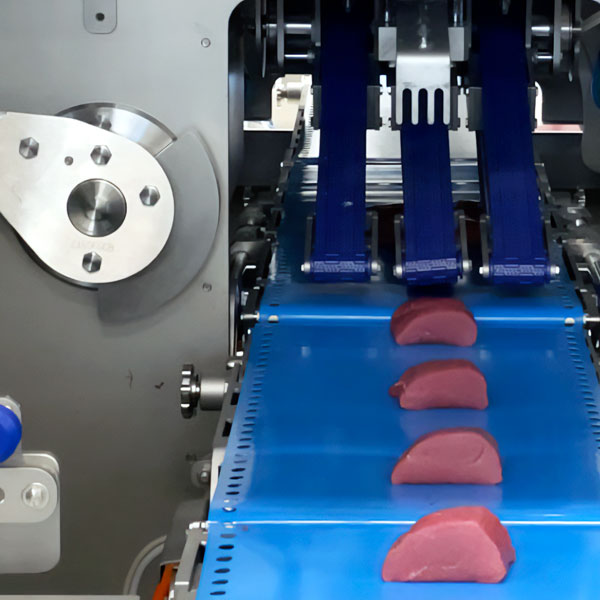

Extreme precision and quality even for thinner slices, in addition to high productivity and yields: the market standard for vertical slicing of fresh meat.

Adjustable cutting parameters and highly efficient, “gentle” technology for the most delicate cuts.

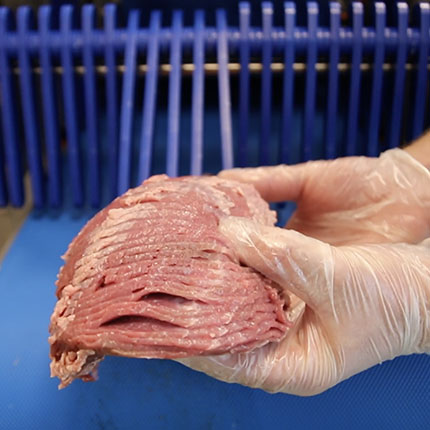

With a cutting capacity of up to 4000 kg/h, KSL CBU is a horizontal slicer for fresh meats with a slice splitting conveyor belt, ideal for poultry meat.

The KSL CBU 3B cuts products with unparalleled precision, automatically separates the slices into three groups and deviates them on three different outfeed belts. Maximum efficiency and extreme flexibility.

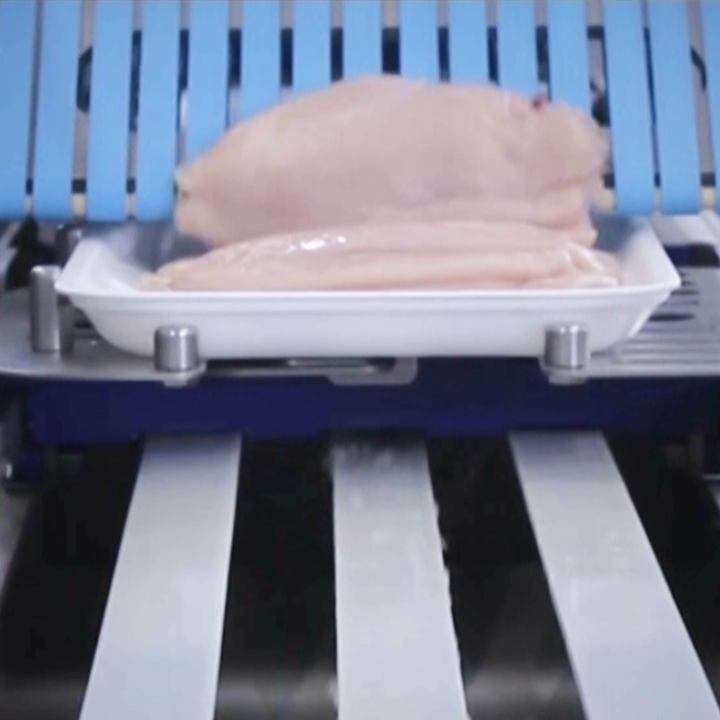

For each chicken breast, according to the recipe settings, the KSL DV automatically decides whether to slice the product, how many blades to use and the ideal slicing thickness.

Fully automatic product infeed and outfeed: an ideal in-line solution for obtaining perfectly even slices also with thinner settings.